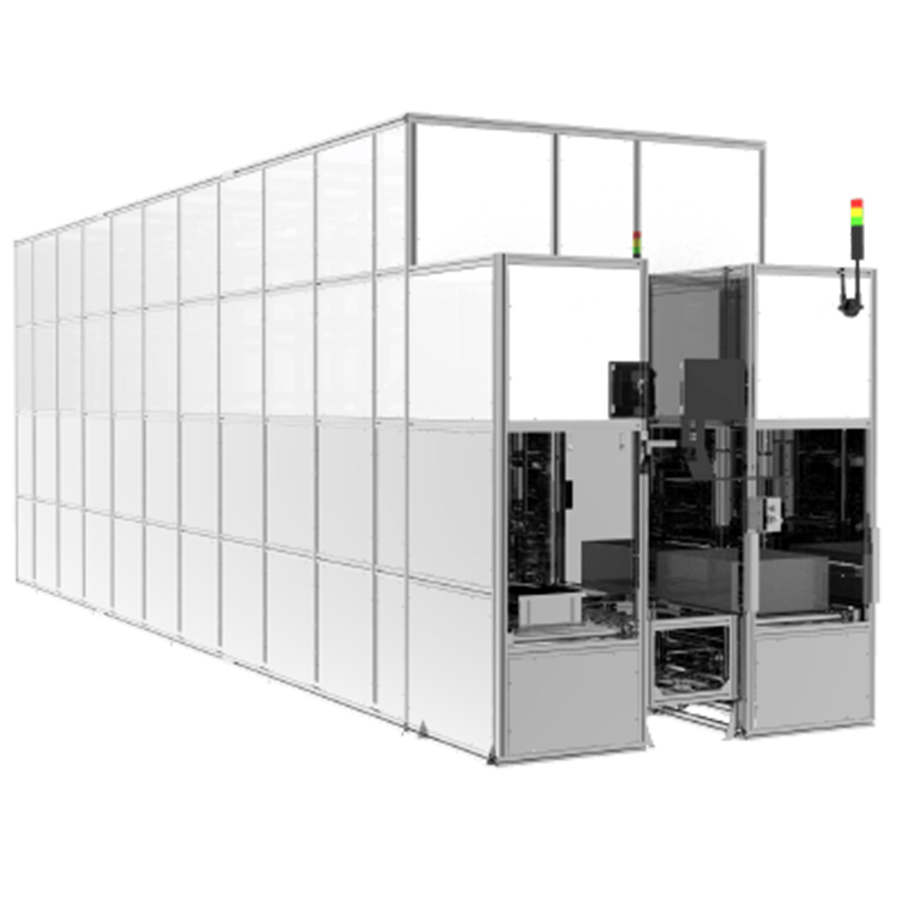

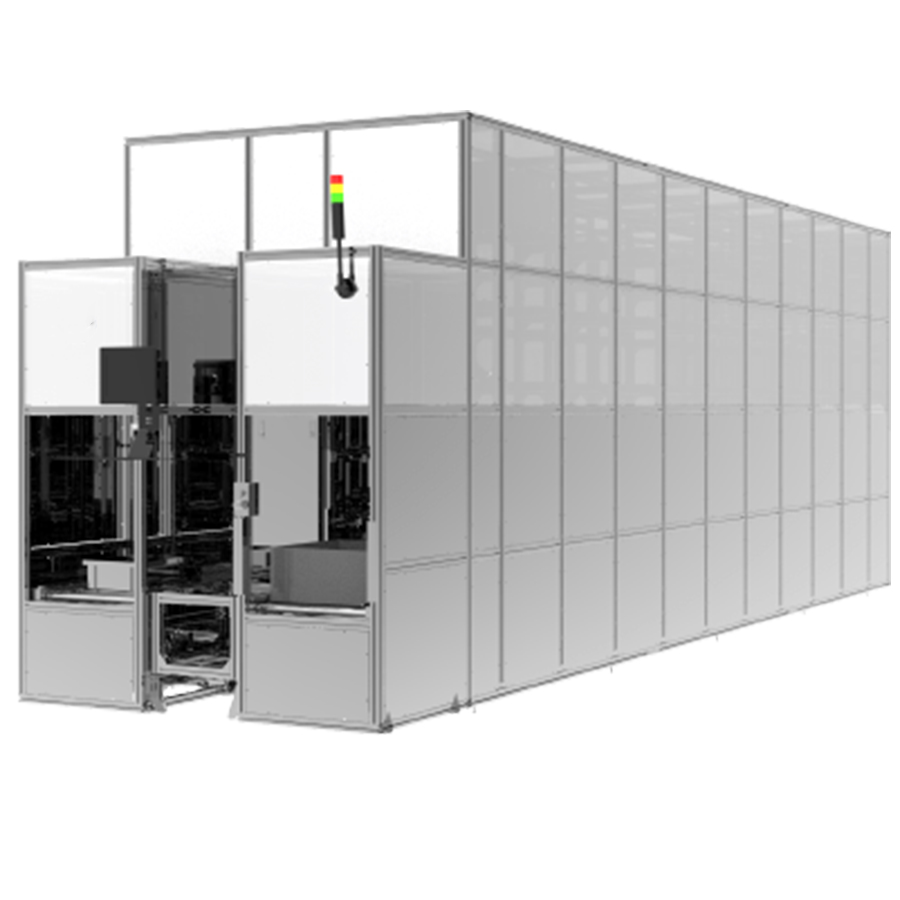

Automated Storage and Retrieval System

SMD BOX XLC

SMD BOX XLC is a container handling equipment developed for automated container storage and retrieval. Automatic container handling provides rapid material flow and considerably increases productivity.

- Capacity: 24 Spool Cable for size 600*450(L*H)

- AGV Integration: Yes

- Material ID Recognition: 1D/2D

- Power Supply: Three Phase 380V

- Power: 4KVA

Specifications

SMD BOX XLC

The SMD BOX XLC is a cutting-edge container-based storage system that streamlines the handling of SMT reels, cables, and wires. Unlike conventional piece-picking systems, it features an internal vertical lift module for efficient container picking and putting. With seamless connectivity, high traceability, and dynamic reporting, the SMD BOX XLC provides a robust solution for managing high-volume and varied electronic materials.

Features

| Feature | Description |

|---|---|

| Container Picking | Employs an internal vertical lift module for automated container picking and putting. |

| SMT Reel Storage | Allows high-volume reel storage in ESD containers within a controlled temperature environment, ensuring economical and efficient storage. |

| Cable & Wire Handling | Automates the management of cables and wires, critical for automotive electronics and other industries, regardless of size or type. |

| Traceability | Tracks material movement with high-grain data, storing component Reel IDs and counting images in a secure database for verification. |

| Dynamic Reporting | Provides real-time, customizable reports and dashboards for smarter decision-making. |

| Connectivity | Seamlessly integrates with IT systems (ERP/SCM/MES/WMS), offering real-time updates on material usage and inventory. |

How It Works

-

Container-Based Storage:

- Unlike traditional SMD BOX systems (SISO/MIMO/XLR), the XLC focuses on container picking for efficient handling of diverse materials.

- The internal vertical lift module automates the process of retrieving and storing containers.

-

Material Management:

- SMT Reels: Stored in ESD containers within a controlled temperature environment, ensuring protection and efficient use of space.

- Cables & Wires: Automates the handling of these critical materials, supporting varied sizes and ensuring a steady supply to production.

-

Traceability:

- Tracks material movements with high-grain accuracy.

- Stores Reel IDs and counting images in a database for auditing and verification purposes.

-

Real-Time Reporting:

- Customizable dashboards and dynamic reports provide actionable insights for material and production planning.

-

Connectivity:

- Powered by Smart Material Flow (SMF) software, the SMD BOX XLC integrates with existing IT systems to provide accurate, real-time data on component usage, storage, and retrieval.

Powered by SMF

The SMD BOX XLC operates on Smart Material Flow (SMF) software suite, which offers a comprehensive range of features:

- Materials Receiving: Streamlined intake process.

- Automated Storage/Retrieval: Maximizes efficiency in managing inventory.

- AGV Control: Supports integration with Automated Guided Vehicles for unmanned operations.

- Component Counting: Ensures precise inventory levels.

- Kitting: Facilitates optimized production workflows.

The SMD BOX XLC is an innovative, container-based storage solution designed to meet the needs of modern SMT manufacturing and other industries requiring precise material management and high storage capacity.