reel materials storage

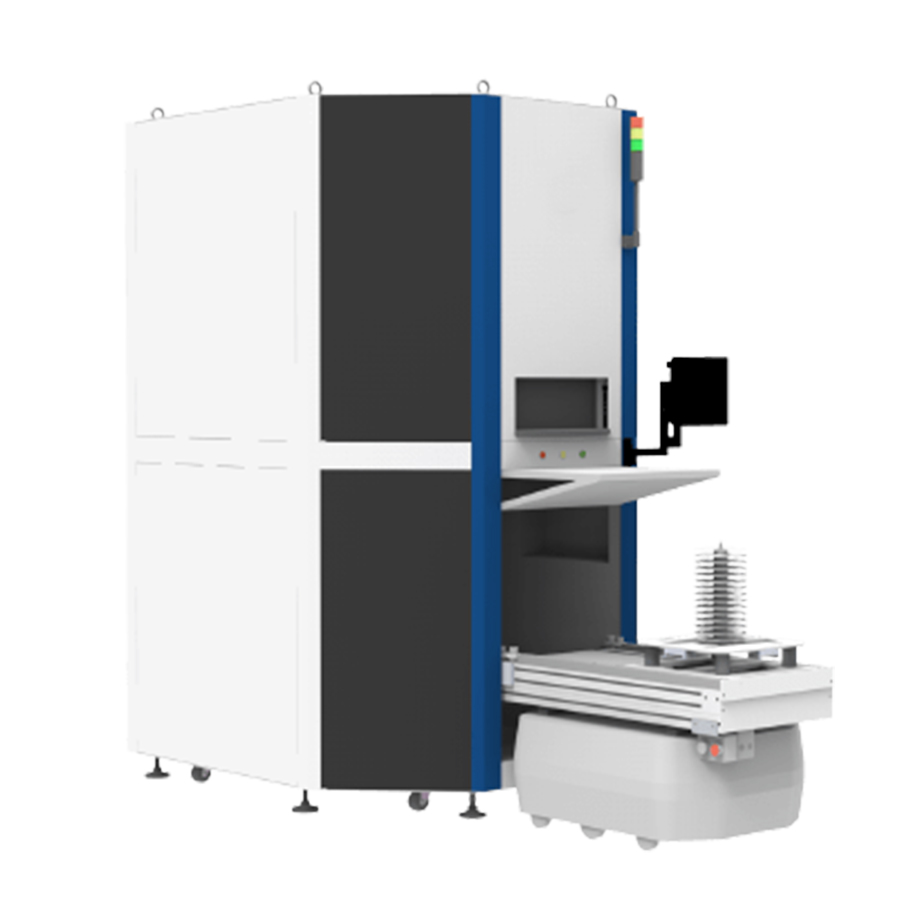

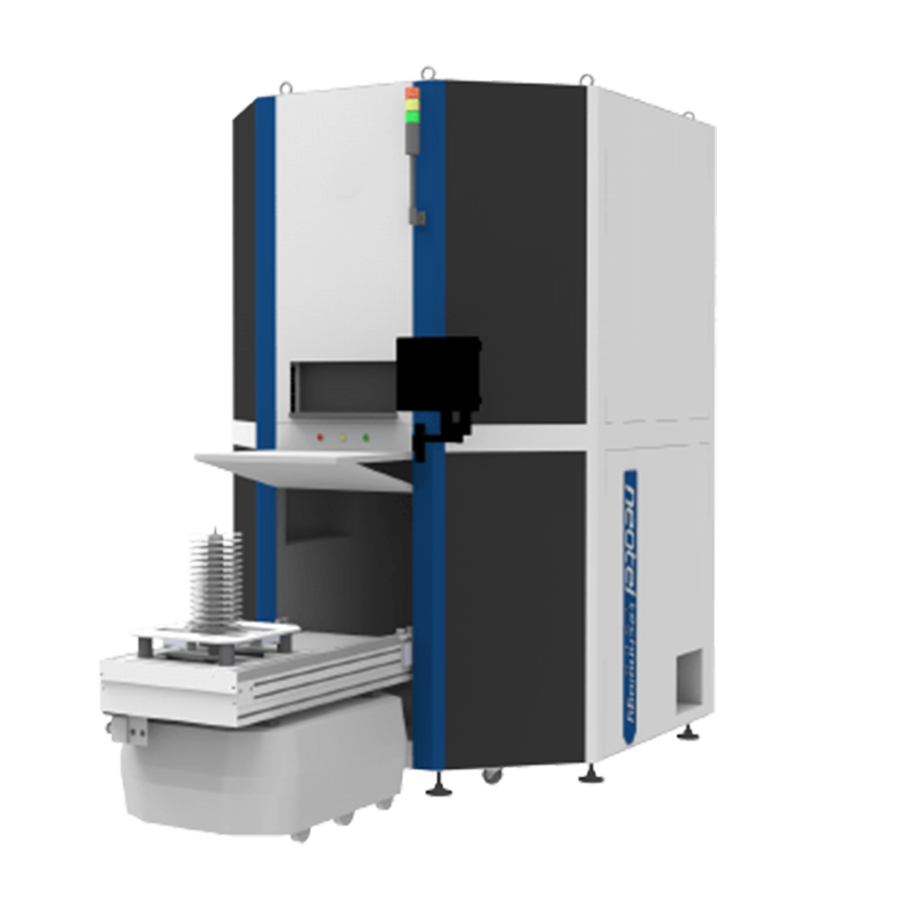

SMD BOX MIMO

SMD BOX MIMO is an SMT tower capable of batch processing SMT reel material storage and retrieval. Users can use a trolley or AGV to load material into the SMD BOX. SMT reels can be kept in the stacker and fed into the loading port of the machine.

- Max Capability: 800

- Material Compatibility: 7,13,15 inch

- Material Info.: 1d/2d

- AGV: Yes

- Power Supply: 220V

Specifications

SMD BOX MIMO

The SMD BOX MIMO (Multi-Input/Multi-Output) is a high-capacity storage and automation solution designed to optimize batch processing in SMT production. With advanced features like AGV integration, MSD tracking, kitting, and automated material replenishment, the SMD BOX MIMO ensures uninterrupted production and streamlined operations.

Features

| Feature | Description |

|---|---|

| MIMO Mode | Enables Multi-Input/Multi-Output operation for batch processing of stacked SMT reels, whether supplied via AGV or trolley. |

| Batch Handling | Automates the retrieval of multiple SMT materials based on a job list or work order. No operator assistance is required. |

| Kitting | Automates kitting and material replenishment by unloading the required reels at the correct time using SMF software. |

| AGV Ready | Integrates with Automated Guided Vehicles for unmanned transport operations. Provides loading ports for AGV to supply or receive SMT reels. |

| MSD Tracker | Ensures compliance with IPC/JEDEC standards for moisture-sensitive devices. Tracks and automates MSD storage/retrieval. |

| MSL Control | Monitors and manages Moisture Sensitivity Levels (MSL) to maintain optimal production quality. |

| Remaining Component Monitoring | Automates material replenishment with real-time component-level inventory monitoring. Generates pick requests for low materials. |

| Component Counts | Updates the component profile with real-time counts of returned components using Neo Counter or X-ray Component Counter. |

| Manual Material Supply | Allows flexibility with manual input for emergency or special operations. |

| Material Info Recognition | Identifies materials using 1D/2D codes for traceability and accuracy. |

| No Material Pallet Needed | Eliminates the need for material pallets, simplifying operations. |

| Reel Compatibility | Supports 7-inch, 13-inch, and 15-inch reels. |

| Connectivity | Seamlessly integrates with MES/ERP systems via APIs for direct communication. |

Powered by SMF

The SMD BOX MIMO operates on Smart Material Flow (SMF) includes:

- Work Order Management: Streamlines production planning and task execution.

- Component Profile Management: Tracks and updates component details.

- MSD Tracker: Ensures compliant handling of moisture-sensitive devices.

- Connectivity Module: Facilitates integration with IT systems via APIs or predefined templates.

Moisture Sensitivity Level (MSL) Control

| MSL Level | Time Limit | Conditions (≤30°C/60% RH) |

|---|---|---|

| 1 | Unlimited | ≤30°C/85% RH |

| 2 | 1 Year | |

| 2a | 4 Weeks | |

| 3 | 168 Hours | |

| 4 | 72 Hours | |

| 5 | 48 Hours | |

| 5a | 24 Hours | |

| 6 | TOL |

The SMD BOX MIMO is the ultimate solution for high-volume SMT production, offering unmatched efficiency, accuracy, and integration capabilities.