FA1240-6x

FLYING PROBE TESTER

Our primary expertise in very precise component testing is utilized by DJK's PCB and substrate inspection equipment. Multi-functional testing can be completed in as little as 0.025 seconds each step with the FA1240 series, a 4-arm populated board inspection instrument.

CE Compliant model: FA1241-61

Specifications

| FA1240-61 FA1241-61 | FA1240-63 | |||||

| Number of arms | 4 (L, ML, MR, R) | |||||

| Number of test steps | 40,000 (max.) | |||||

| Measurement ranges | Resistance: 400 μΩ to 40 MΩ Capacitance: 1 pF to 400 mF Inductance: 1 μH to 100 H Diode VZ measurement: 0 to 25 V Zener diode VZ measurement: 0 to 25 V, 25 to 80 V (optional feature) Digital transistors: 0 to 25 V Photo couplers: 0 to 25 V Short: 0.4 Ω to 400 kΩ Open: 4 Ω to 40 MΩ DC voltage measurement: 0 to 25 V | |||||

| Measurement time | Max. 0.025 sec./step | Max. 0.025 sec./step | ||||

| Probing precision | Within ±100 μm for each arm (X and Y directions) | |||||

| Positioning repeatability | Within ±50 μm (probing positions) | |||||

| Inter-probe pitch | Min. 0.15 mm Min. 0.5 mm (when using 4-terminal probes) | Min. 0.15 mm Min. 0.5 mm (when using 4-terminal probes) | ||||

| Testable board dimensions | 510 mm (20.08 in) W × 460 mm (18.11 in) D | 400 mm (15.75 in) W × 330 mm (12.99 in) D | ||||

| Power supply | 200 V AC (single-phase), 50/60 Hz, 6 kVA (FA1241: 230 V AC) | 200 V AC (single-phase), 50/60 Hz, 5 kVA | ||||

| Dimensions and mass | 1406 mm (55.35 in) H × 1300 mm (51.18 in) H × 1380 mm (54.33 in) D, 1150 kg (40,564.4 oz) | 1266 mm (49.84 in) H × 1369 mm (53.90 in) H × 1425 mm (56.10 in) D, 1050 kg (37,037 oz) | ||||

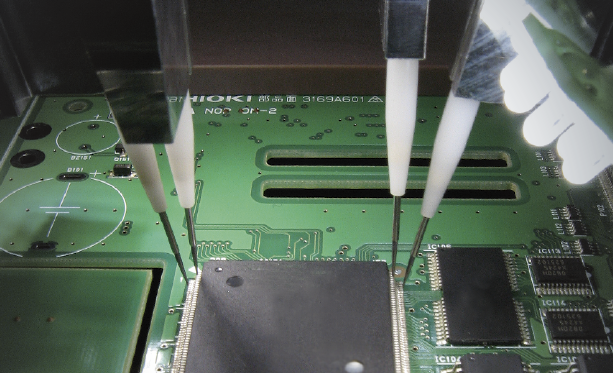

Correct mounting is confirmed by electrical testing.

Create a program based on the design data, perform electrical testing in a timely and cost-effective manner, and promptly confirm and record problems.

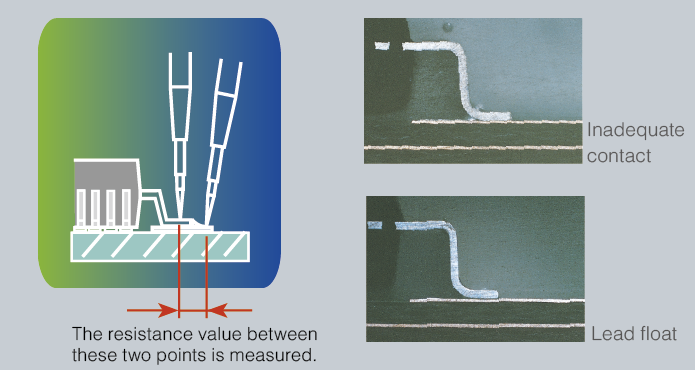

Lead float and pseudo-contact are not the same.

Pseudo-contact of leads is a sort of fault that can pass through multiple testing during the board manufacturing process and make it to market. Lead float may be successfully recognized using today's image inspection technology.As a result, DJK's unique resistance measuring pseudo-contact test detects pseudo-contact, which is difficult to recognize based just on appearance.

Highlighting the significance of test points and Gerber data

To suggest that the ability to readily create data is different from the ability to easily test boards is half true and half false.In the discrete age, being able to create data might have meant testing boards more readily. However, in order to create the test data required by the FA1240, it is crucial that the process of creating reliable test data be straightforward and easy to carry out.

It is feasible to reduce production line downtime (to enable debugging and other adjustments) and ship products with confidence by reducing the gap between data suitable for operating the tester and data suitable for product shipment.

Just adhere to the process.

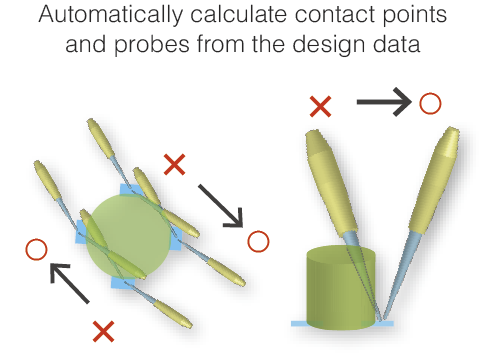

Programs that finish quickly and account for component height

Arm interference is automatically calculated while using the UA1780.

Do you examine probe tips to see whether or not they will strike components on the board when checking data? Actually, selecting probes used to be a difficult and time-consuming step in the debugging process that needed careful consideration.You may approach the work of debugging electrical testing with confidence since the FA1240 can automatically choose the right test probe by adding component height information to mounting data.

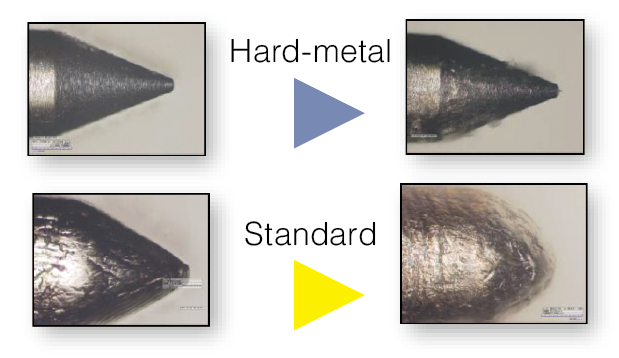

Extended-life probes (extended service life and easy replacement)

Even after three million contact cycles, the tips of DJK's new super-hard probes exhibit no wear. Up to 3,000,000 uses of stable contact that avoids pseudo-contact from slides

FAQ's

Frequently Asked Questions

A Flying Probe Tester (FPT) is a type of automated test equipment used for checking the functionality and quality of printed circuit boards (PCBs). Unlike traditional test systems, it uses movable probes to access test points without requiring custom test fixtures.

- Flexibility: No need for custom fixtures, making it ideal for small production runs and prototyping.

- Cost-Effective: Lower setup costs compared to traditional in-circuit testers.

- Fast Debugging: Quick setup and test program generation for design changes.

- High Accuracy: Advanced probes offer precise measurements and diagnostics.

Flying Probe Testers can conduct a variety of tests, including:

- Continuity and isolation testing.

- Component value testing (resistors, capacitors, etc.).

- Short-circuit detection.

- Diode and transistor testing.

- In-circuit functional testing (with optional fixtures).

While FPTs are excellent for low to medium production volumes, prototyping, and design validation, they are generally slower than fixture-based testers for high-volume manufacturing due to their sequential testing process.

- Flexibility: FPT does not require custom fixtures, making it ideal for prototypes or frequent design changes, while ICT relies on dedicated fixtures for speed.

- Cost: FPT has lower initial costs due to the absence of fixture creation.

- Speed: ICT is faster for high-volume production, while FPT is better suited for smaller runs.