Our Trusted Suppliers

Products & Equipments

-e1742530729484.jpg)

As a leading distributor of SMT Equipment, we partner with globally recognized manufacturers to provide a comprehensive range of solutions. From precise component placement to advanced soldering and inspection, our portfolio is designed to optimize your SMT production line and drive efficiency. We are committed to building long-term partnerships based on reliability and trust. Our equipment is sourced from industry-leading manufacturers known for their quality and performance. You can rely on us to deliver consistent results and exceptional value.

Printer

-

Printing cycle time of 12 seconds

-

Repeated positioning accuracy of ±3.8 μm

-

Model changeover and solder transfer and supply automation reduce production time and machine downtime

-

Incorporates unit cleaning for each cycle and optimized maintenance timing

Pick & Place

-

Broad Component Handling from ultra-small (0402/01005) to large connectors, odd shapes, and advanced packages (PoP, BGA).

-

Handle diverse PCB sizes and types.

-

Achieves high placement speeds with advanced vision and lightweight heads for increased accuracy.

-

Flexible and Adaptable Production

-

Optimize your factory space with a compact footprint, and scale production seamlessly to meet your growing demands.

Board Handling Equipment

-

Transports printed circuit boards efficiently.

-

Automates PCB movement, reduces errors.

-

Enables seamless production line flow.

-

Improves speed and manufacturing precision.

-

Critical for high-volume PCB assembly.

SPI

-

Ensures print quality, reduces defects.

-

Measures volume, height, and area.

-

Critical for reliable solder joints.

-

Prevents costly rework, improves yield.

-

Automated, fast, and highly accurate.

AOI

-

Fast, automated defect detection, visual analysis.

-

Increased manufacturing precision, reduced human error.

-

Improved product quality, consistent inspections.

-

Cost-effective, efficient production monitoring.

-

Enhanced process control, real-time feedback.

Reflow

-

Achieving high productivety by high speed, high precision and high power

-

Achieving high yield of workpiece by stable machining

-

Easy operation of peripheral equipment by high expandability

Soldering

-

Automates circuit board soldering processes.

-

Wave: mass soldering for PCBs.

-

Selective: precise, component-specific soldering.

-

Robotic: flexible, programmable solder application.

-

Improves consistency, reduces defects.

Coating Machine

We provide equipments, fabrication and installation of painting / powder / fluorocarbon / coating systems.

Depaneling Machine

-

Precise circuit board separation, reduced stress.

-

Automated routing, consistent quality, higher throughput.

-

Minimizes dust, debris; improves cleanliness.

-

Programmable paths, adaptable to board designs.

-

Optimized for delicate components, less damage.

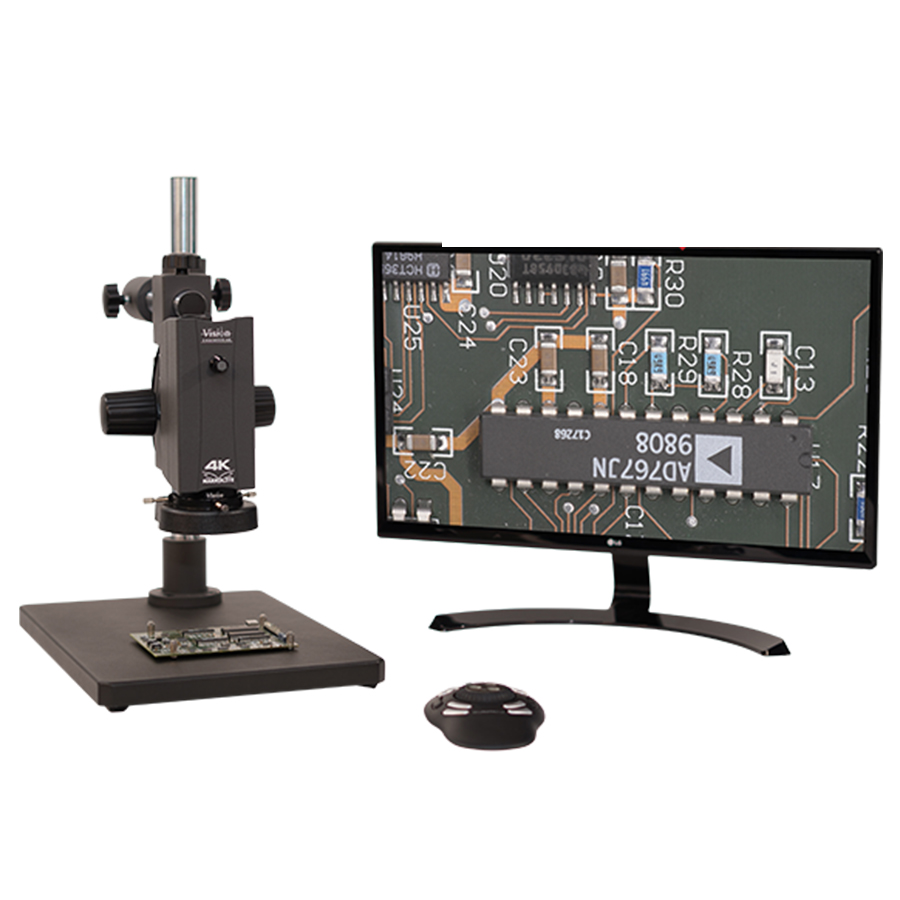

Peripheral

-

Microscope: Precision inspection, detailed component analysis and repair.

-

BGA Rework Station: Accurate chip removal and replacement, critical repairs.

-

Stencil Cleaner: Ensures precise solder paste application, quality yields.

-

Profiler: Thermal analysis, optimizes soldering, reflow oven control.

-

Solder: Essential material, reliable electronic connections, varied types.

-e1742530729484-ra9072d4sbfudf1u47kajkd7rqnggxanbhi8x5abe4.jpg)

-ra9072d4sbfudf1u47kajkd7rqnggxanbhi8x5abe4.jpg)