Advanced Inspection Systems

Solutions for the Healthcare Industry

We specialize in providing equipment for the pharmaceutical industry, including visual inspection systems for tablets and capsules, tablet printing inspection systems, and other automated packaging lines for solid medications and injectables. To highlight our industry excellence, we are aggressively developing innovative next-generation systems in collaboration with equipment manufacturers such as our group firm Daiichi Jitsugyo Viswill Co., Ltd. and business partners, with the goal of bringing them to market.To its credit, Viswill has been serving this Pharma industry nearing 5 decades now, with more than 2000 Inspection machines in their Sales record worldwide. The company has been dedicated in delivering the highest quality in Inspection standards, that makes the top 10 pharma companies in Japan employ more than 250 machines of Tablet inspection, that leads to their High end quality product to the world. One of the key point of Viswill’s growth has been to be contemporary and updated on the machines in line with the customer needs.

Not only to the OSD but DJK also is dedicated to injectables and Vaccine industry where we have partnered with HITACHI for high resolution inspection for the particle and cosmetic inspection.

With an aim to provide highest and latest technological advancement to vaccine industry we have partnered with Shikoku instrumentation company for Manipulator and Waken B Tech for CO2 Incubator, etc.

Track & Trace, Serialization, Checkweigher, X-ray scanner

We provide high performance and customer-oriented solutions of Track & Trace, Serialization, Checkweigher and X-ray scanner from Germany which are built with the highest engineering skills. All of them are one of the world’s leading technologies and most installed, used systems in the world.

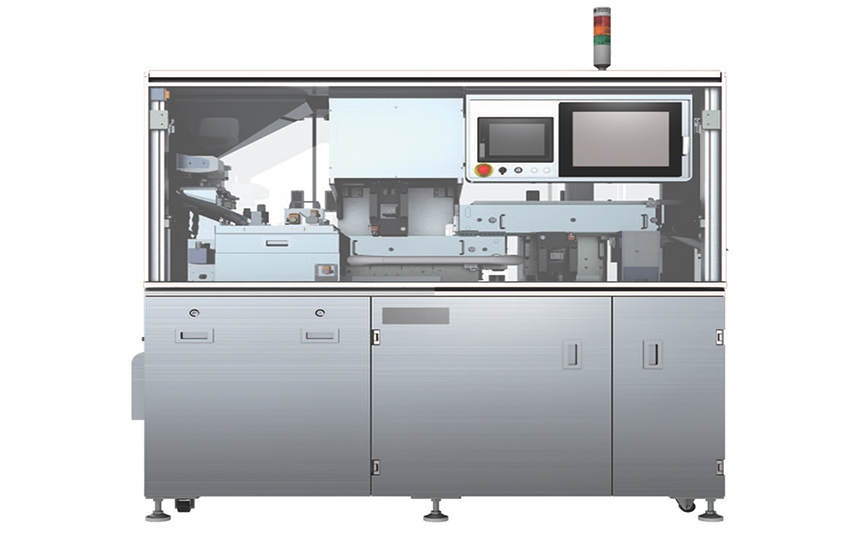

Tablet / Capsule Visual Inspection System

More than 2,000 units of the advanced visual inspection systems for pharmaceutical industry manufactured by our affiliate Daiichi Jitsugyo Viswill has been sold, making it a market leading product.

Viswill original 3D inspection and image processing technology, stable transfer system and all other unique technologies enable us to be No.1 market share in the world of pharmaceutical visual inspection systems.

Color / Vacuum suction / Electrostatic Sorters

These sorters are designed for pharmaceutical processing, food processing, tea processing, medical processing and other industrial purposes.

Based on the great deal of experiences and extensive installation history, we choose the best method to various kinds of materials and products to be sorted accurately and efficiently by our machines.

Once a product sample is provided, we conduct evaluation test to find out which method is suitable, how accurate it is, and how much the processing speed is.

Granular Inspection System

Granular inspection system accurately detects and removes foreign materials contaminated in granules and powder. Stable detection of not only black foreign materials and hairs, but also fine light colored foreign materials and discolored foreign matter.

It has a maximum throughput of 150kg/h, a maximum detection accuracy of 50μm, as well as easy maintenance.

The system helps to improve the efficiency of inspection of granules and powders and to improve safety and quality control for customers’ productions.

Semi-Automatic Vial Inspection Machines

This Semi-Automatic Vial Inspection Machine can change the angle of vials transported by conveyor as suitable for defects to be inspected.

The angle can be designed from 60° to -45°.

Defects which can be inspected are cap and seal, crimp, rubber stopper, top/side/bottom of cake, etc.

Please contact us for more details.