We specialize in providing equipment for the pharmaceutical industry, including visual inspection systems for tablets and capsules, tablet printing inspection systems, and other automated packaging lines for solid medications and injectables. To highlight our industry excellence, we are aggressively developing innovative next-generation systems in collaboration with equipment manufacturers such as our group firm Daiichi Jitsugyo Viswill Co., Ltd. and business partners, with the goal of bringing them to market.To its credit, Viswill has been serving this Pharma industry nearing 5 decades now, with more than 2000 Inspection machines in their Sales record worldwide. The company has been dedicated in delivering the highest quality in Inspection standards, that makes the top 10 pharma companies in Japan employ more than 250 machines of Tablet inspection, that leads to their High end quality product to the world. One of the key point of Viswill’s growth has been to be contemporary and updated on the machines in line with the customer needs.

Not only to the OSD but DJK also is dedicated to injectables and Vaccine industry where we have partnered with HITACHI for high resolution inspection for the particle and cosmetic inspection.

With an aim to provide highest and latest technological advancement to vaccine industry we have partnered with Shikoku instrumentation company for Manipulator and Waken B Tech for CO2 Incubator, etc.

Encapsuling and related machines

Suited to integrated production lines for capsules. We provide comprehensive solutions, including design of entire production lines and GMP compliance.

Our line-up starts from capsule filling machines which offer several types of filling method according to drug nature, hard gelatin capsule sealing machine and checkweighers, to ensure producing high quality products.

Tablet Presses

Adopting a separated self-standing type touch panel computer, it is a PIC/S GMP compliance tablet press which achieves high performance as well as affordable price. There are various line-ups from middle to large model, and single layer to bi layer model, which can meet customers’ requirements.

Patches and Medical Adhesive Tapes Manufacturing Machines

Manufacturing machines for various types of medicals tapes such as first-aid adhesive bandages, patches, plasters, and transdermal drugs.

We have a great number of experience in the installation of integrated production lines that handle everything from ointment applying to inspection and packaging.

We can design machines and lines to meet your products and special requirements.

Please contact us for more details.

Auger-type Powder Filling Machines

The machine manufacturing is based on more than 50 years of experience and can be used for all kinds of powders.

The filling volume range is significantly wide as from 10mg to 30kg, and the filling container can be any kind of container such as paper bag and plastic bottle, as well as vial, ampoule, double bag, drum, etc.

We can also handle special specifications such as the filling of fine powders and aseptic filling.

Please contact us for more detail

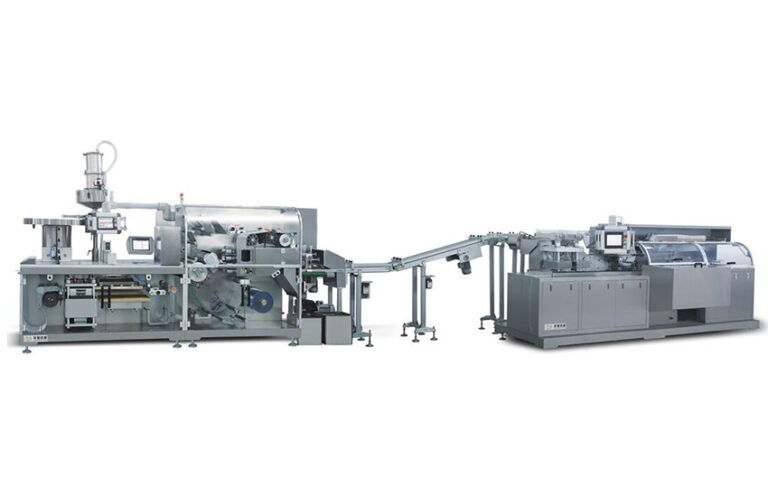

PTP Blister Packaging Lines

We sell a PTP blister packaging line which realizes flat panel consecutive molding, which was not realized in the past. Therefore, we can give solutions to customers employing conventional flat panel intermittent molding.

We also sell a 4 direction-sealed packaging line which enables all sheet gauges by weight checkers and automatically adjustable mass measuring with the cutting margin of packaging material being as little as possible, utilizing a patented technology called film constant tension systems. In addition, we recommend a high-speed packaging line which realizes 2,000 packagings (6 rows) per minute which is the world’s fastest packaging speed.

Medical Device Manufacturing and Inspection Machines

For medical device providers, we provide a suite of solution, e.g. molding machine, syringe assembling machine, needle glinder, inspection machines for all those machines and so on.

As we are Japan based trading company, we provide reliable Japanese quality machines and our expertise will provide one stop solution from engineering stage to commissioning.