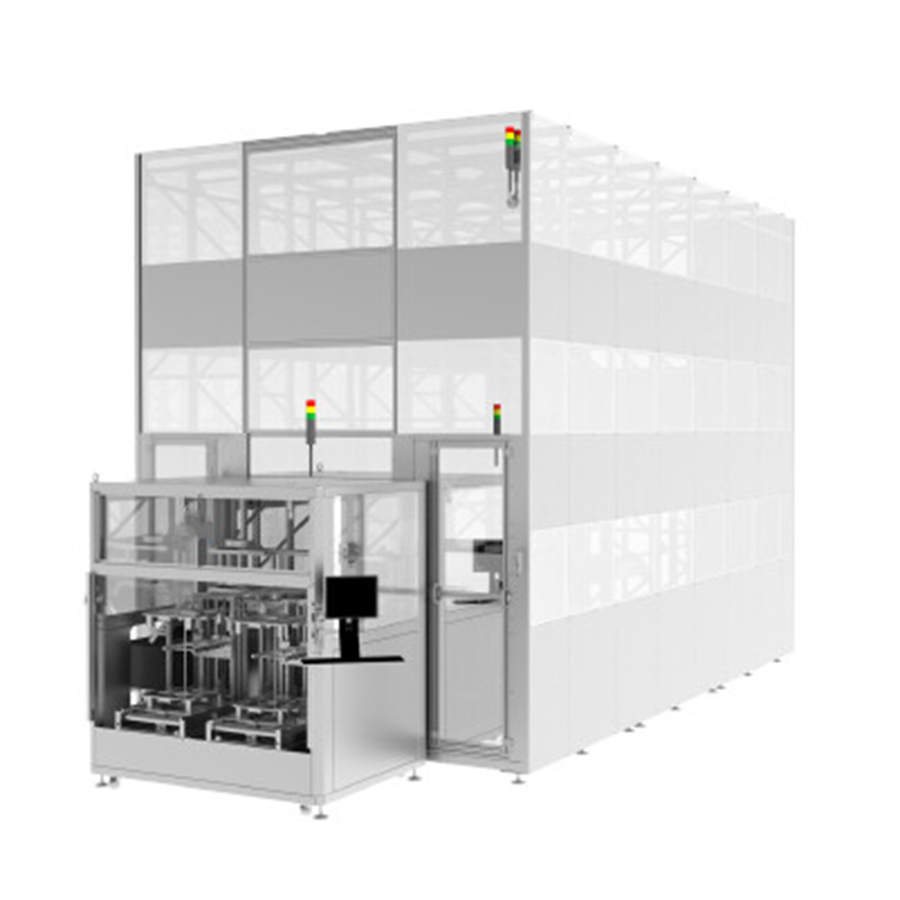

High volume SMT storage

SMD BOX XLR

SMD BOX XLR increases the storage capacity to 14400 reels. SMT storage tower is capable of batch processing SMT reel material storage and retrieval operations. Users can use a trolley or AGV to load material into the SMD BOX. SMT reels can be kept in the stacker and fed into the loading port of the machine.

- Storing Capacity:14400 reels

- Material type: 7-15 inch reel

- Tray: Yes

Specifications

SMD BOX XLR

The SMD BOX XLR is an advanced storage solution designed for high-volume SMT manufacturing environments. With its integration-ready connectivity, AGV compatibility, and cutting-edge Smart Material Flow (SMF) software, it automates and streamlines material handling and storage, enabling maximum efficiency and traceability.

Features

| Feature | Description |

|---|---|

| AGV Ready | Equipped with loading/unloading ports for Automated Guided Vehicles (AGVs), enabling unmanned transport of SMT reels, PCBs, and containers. |

| High Storage Capacity | Accommodates up to 14,400 reels, making it ideal for high-volume production requirements. |

| Connectivity | Seamlessly integrates with IT systems (ERP/SCM/MES/WMS), providing real-time updates on component usage and inventory. |

| Traceability | Tracks material movements with high-grain data, storing component Reel IDs and counting images for future verification. |

| Reporting System | Generates dynamic, real-time reports with custom dashboards for smarter, data-driven decision-making. |

How It Works

-

AGV Integration:

- AGVs supply or retrieve groups of SMT reels (in stackers) to/from the SMD BOX XLR ports.

- The system automates the storage or retrieval of materials, reducing manual intervention.

-

Connectivity:

- With SMF software, the SMD BOX XLR integrates seamlessly into your IT ecosystem, ensuring accurate, real-time material tracking and management.

-

Storage & Retrieval:

- High-volume storage capacity supports up to 14,400 reels, ideal for large-scale production environments.

- Automation ensures materials are stored and retrieved efficiently and accurately.

-

Traceability:

- Tracks every component entering or exiting the system.

- Stores component Reel IDs and X-ray counting images in a secure database for auditing and verification.

-

Dynamic Reporting:

- Custom dashboards allow users to monitor key metrics in real-time.

- Reports can be saved, shared, and used for smarter production planning.

Powered by SMF

The SMD BOX XLR is powered by Smart Material Flow (SMF), Comprehensive software suite for material control and automation. Key features include:

- Material Receiving: Simplifies the intake process.

- Automated Storage/Retrieval: Enhances workflow efficiency.

- Component Counting: Ensures inventory accuracy.

- Kitting & AGV Control: Streamlines material handling for optimized production.

The SMD BOX XLR offers an unmatched combination of high-capacity storage, advanced connectivity, and automated material management, making it an essential solution for modern SMT manufacturing.